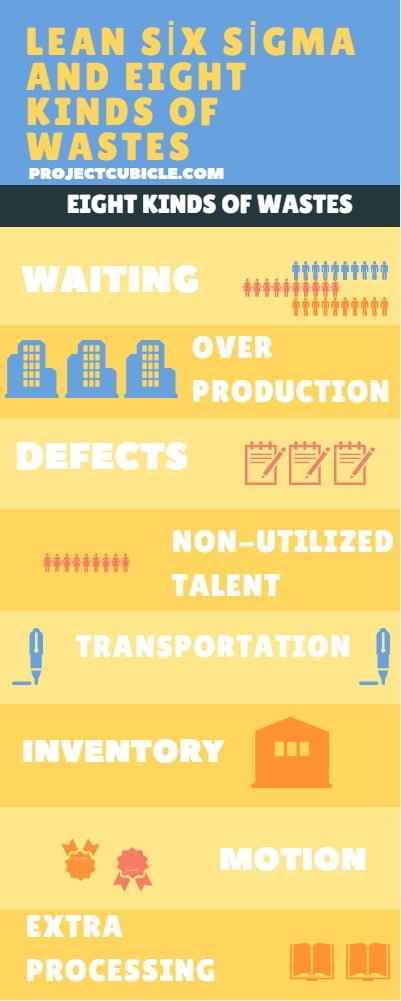

The work in progress or finished goods in addition maintains a cost and until it is sold, that cost is of the business. Inventory always costs money, as every single piece of product is tied up in raw material. Time wasted waiting on an engineer or team member, is a particularly uncertain and pervasive form of waste, often through more bureaucratic processes, which can take a long time to remedy or minimize.

It is regarded as an apparent waste, as it adds zero value to the product.ĭuring our daily lives, we continue to waste enormous quantities of time waiting for possible things.

The movement of products from one place to another is associated with transportation. are two of the more destructive forms that overproduction can take in lean methodology. Overproduction leads to high inventory levels which can obscure many of your organization's complex problems.īatch processing, creating more supply than demand, etc. Defects are not always the easier ones to be detected before they typically reach potential customers.Īny mistakes made during production, or with the products themselves, come at a significant cost. In Lean philosophy, the best way to properly explain waste is as "Stuff that doesn't add value."Ĭonsumers would not be able to pay for any activity that does not add value to what they essentially want.ĭefects are the most common of the seven wastes. In Lean, the 7 wastes are popularly known as the origin of all unprofitable behavior within an organization. Optimization of primary resources that lead to specific improvements among others.Gradual reduction or possible elimination of defect generation chances.Product or service delivery time improvement.The lean methodology helps in various business activities and offers benefits such as. It also promotes a continuous chain of improvements as it is a never-ending process of chunking out waste. The Lean approach ensures outstanding quality and satisfaction for the customers. This methodology stresses the elimination of unnecessary steps in a process and the only steps to add value. Lean represents a systematic approach to reducing or removing work that does not include value to the process or method. What is Lean? What are the Benefits of Lean Methodology? People with no experience in this field can also get an idea of what these methodologies are all by reading this article. Related read: Six Sigma Certifications - Reasons Why you Should Get Them

However, being here you are at the right stop, as we will introduce you to the methodologies in Lean and Six Sigma When a person starts to think about the fundamental principles of streamlining a business operation, they tend to discover what the process is all about through different mediums. Introduction to the Concept of Lean, Six Sigma, and Lean Six Sigma Methodologies Lean and Six Sigma in Quality Management – Why is it Important?.What are the benefits of using the lean six sigma methodology?.What is Lean? What are the Benefits of Lean Methodology?.Introduction to the Concept of Lean, Six Sigma, and Lean Six Sigma Methodologies.

0 kommentar(er)

0 kommentar(er)